9. Bio-production

My final project is aimed towards making a nanometric, high resolution “bio-canvas”. I propose how to create a chip of area 10 microns squared which can contain 1M addressable “pixels”, using immobilized single DNA strands.

For this week, we need to think how could we use Ginko’s platform for my project. I see two paths where I could leverage the Foundry to my proposal, around automation.

Automatic Ligation-Sequencing Loop

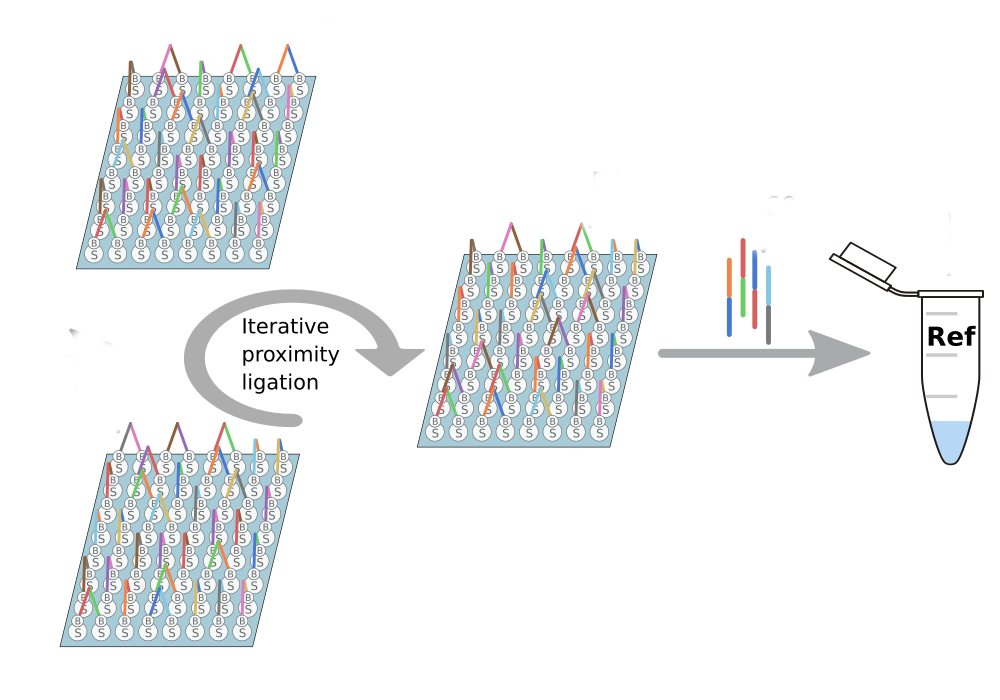

The first step in creating the nanometric bio-canvas is to spread random DNA barcodes on a surface of a chip. The barcodes are immobilized using Biotin-Strepavidin bonds. Then we start a process of iterative proximity ligation, something like that following protcol:

- Flow DNA connector strand and DNA ligase on the chip

- Wash

- Flow DNA primers and DNA polymerase on the chip

- Wash

- Melt off polymerized DNA strands, wash and store in a tube

- Repeat many times

All of the strands in the tube are sent for sequencing. If we have enough reads, the coordinate of each immobilized barcode is recovered, and the canvas is ready to be “painted”. If not… we need to repeat the process more times.

Using Ginko’s automation platform, the above process can be done much more efficiently. First of all, the flow and wash steps off the chip can be fully automated. More interestingly, using Ginko’s abilities, the usual workflow of collecting many samples in a tube and send that off to sequencing, and wait - it could be much more efficient to perform live dynamic sequencing. After each step, the polymerized strands are sent straight down the pipeline for sequencing (along with addition barcodes for de-multiplexing, to fit with Ginko’s platform). While it’s a relatively small number of strands/read, it’s efficient because it can happen in parallel of the other process running in the Foundry (or other bio-canvases in the making). Then, the results from the sequencing are read and we know if we have enough sequences or we need to repeat. Meaning, the protocol becomes optimal and we do exactly as many steps as needed, thus saving reagents and time.

DNA Library Synthesis

In the second part of the project, once we have prepared the bio-canvas, it’s time to paint it. To do so, we need a way to generate a pool of barcodes attached with whatever we want to paint over the surface, e.g. fluorescence group. If our canvas has 1M pixels, we will need on average 0.5M barcodes to paint it. And to be precise, I don’t mean 0.5M …NNNN… barcodes, but a specific, pre-defined list. Here, Ginko’s tools also seem to come in handy, as they offer DNA synthesis at scale services. Not sure exactly what’s the price from the website, but the tools and knowledge within Ginko seems to imply that they could offer an industry leading quota on a generation of such a big library.